Hot Pass Pipe Welding Techniques

How to Do a How Pass on Pipe in the 6G Position Using a E7018 Electrode

This is a countiation of the previous page on open root welds and now we are moving on to how to do a hot pass in the 6G position.

What is a Hot Pass Used For?

The hot pass is defined as the 2nd to 3rd pass on the pipe that is done to cover the root weld. If done right the hot pass will turn a flat root penetration surface to a convex one. If your root weld does not have enough penetration or even some suck back a good hot pass can fix that!

The way a hot pass gives the root better penetration comes from welding hot and making sure the toe of the weld heat up the outsides of the pipe bevel. When the pipe cools and shrinks the root is forced to protrude on the inside of the pipe and become convex.

Hot Pass Welding Technique and Rod Angles

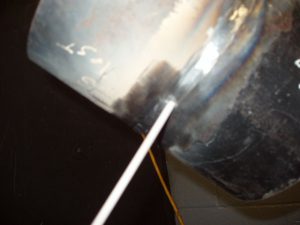

My hot pass or filler pass was done using a weave with a 3/32 E7018 electrode. The technique I used was to hold the sides until the toe of the weld washed into the bevel. The upper part of the bevel was held about 2 seconds and the bottom was held for about 1 second. This is the easiest part of the welding certification.

How to Do a Hot Pass In The 6G Position

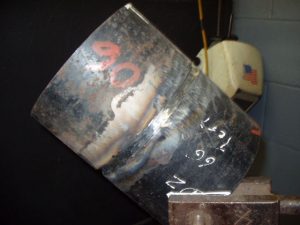

Before putting in the hot pass I grinded down the roots surface. When it comes to welding certifications some inspectors do not allow grinding at all but with the E6010 root they almost always allow to grind down the root. Most of the time everyone piggy backs there tacks, so you will have a few lumps on the outside of the root from the restarts. When it comes to grinding down the roots surface on critical joints it is always allowed.

Here is are the pictures of my hot pass. I used a weaving technique for my weld holding the sides just like the above pictures of the electrode angles. As you can see the bevel is mostly filled and there is no slag on the edges of the bevel. When putting in a filer pass the slag should come off pretty easily! If not, that means you are not holding the sides long enough and there is a possibility of slag inclusions.

Next page: Pipe Welding Techniques for The Cap

Contents overview of the 6G pipe welding certification: